Paper published in Nature Communications: Effect of hydrogen on the integrity of aluminium–oxide interface at elevated temperatures

Following the findings of nanoscale origin of hydrogen blistering at room temperature (Nature Materials, 2015) and the mechanism of hydrogen-dislocation interaction (Nature Communications, 2016), researchers in CAMP-Nano recently revealed the microscopic mechanism of hydrogen induced interface failure at elevated temperatures. This work is published in Nature Communications on Feb. 20, 2017.

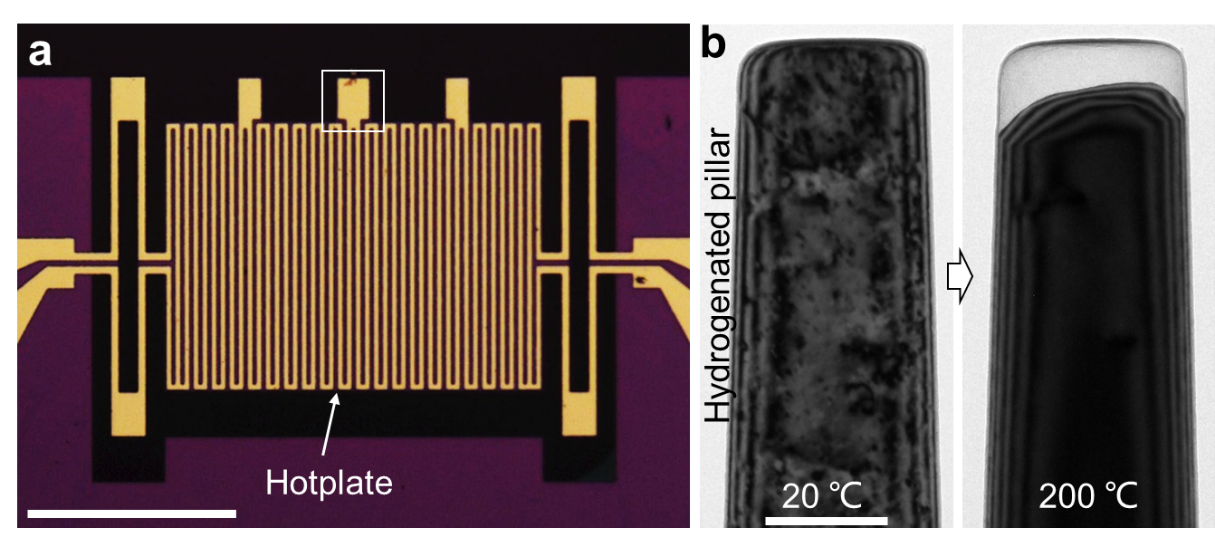

Figure 1. a, the homemade ultra-stable MEMS heating chip, b, the formation of giant cavity of hydrogenated pillar after heating

As the lightest element in the world, hydrogen can easily get into other materials, causing interface failure or forming internal porosity, and hence greatly degrade material performance. These processes are usually related to temperature variation, such as in petrochemical factories, nuclear plants, and metallurgical process. However, despite its huge industrial significance, the underlying physical mechanism of hydrogen effect at elevated temperature remain elusive, especially at atomistic scale due to the limitation of technology.

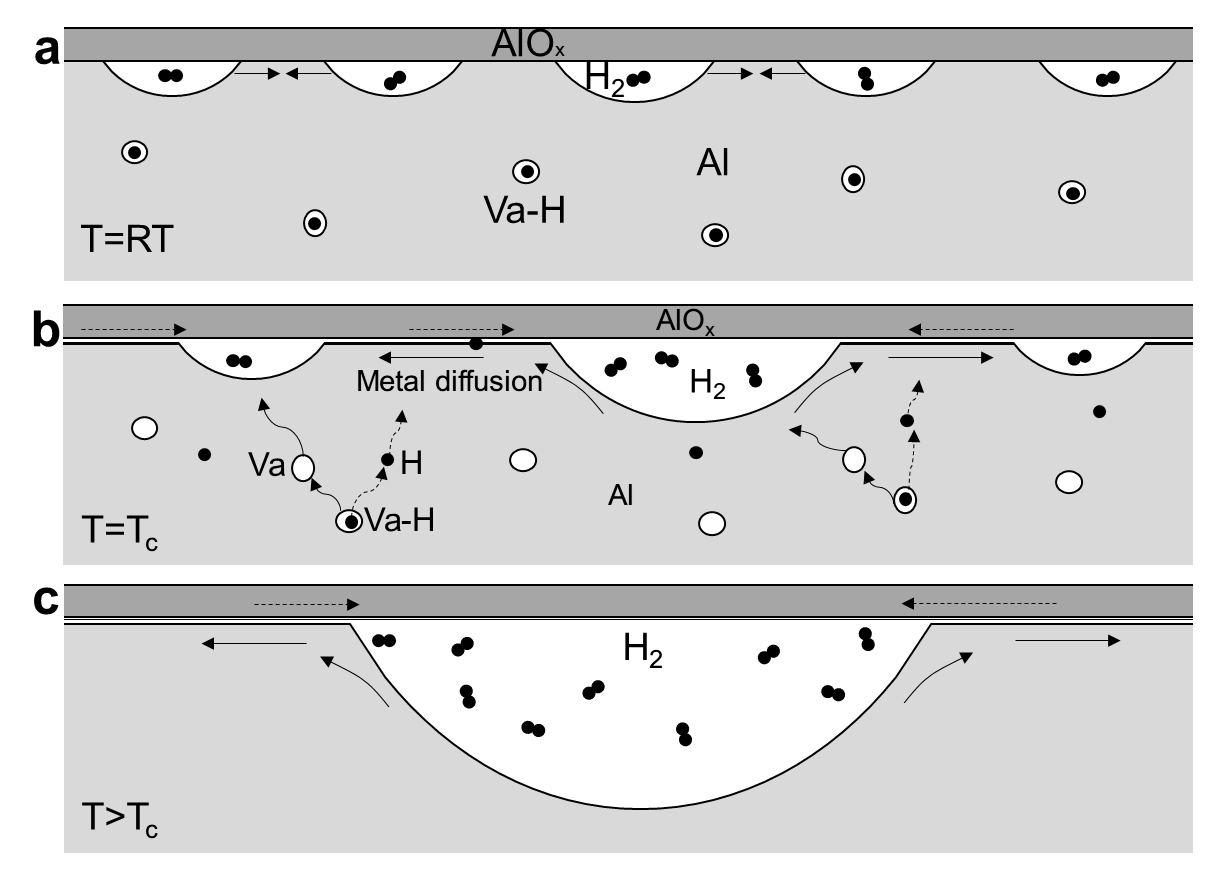

Figure 2, Schematic illustration of the giant cavity formation process.

Under the supervision of Prof. Zhiwei Shan, Meng Li, a Ph.D student of CAMP-Nano, collaborated with Prof. Xixiang Zhang in KAUST, Saudi Arabia, and developed a quantitative home-made ultra-stable MEMS heating device, which overcame the multiple challenges of large thermal drift, inaccurate temperature and difficulty in bulk sample preparation in current in-situ heating devices. This device has the minimum thermal drift comparing with existing devices, and can easily prepare samples from bulk material, hence enabling in-situ monitoring of microstructure evolution in response to temperature change at unprecedented high spatial resolution. With this unique device, by heating hydrogenated aluminium inside an environmental transmission electron microscope, Meng Li and Dr. Degang Xie found that hydrogen exposure of just a few minutes can greatly degrade the high temperature integrity of metal–oxide interface. Moreover, there exists a critical temperature of ~150 °C, above which the growth of cavities at the metal–oxide interface reverses to shrinkage, followed by the formation of a few giant cavities. Although these changes proceed vigorously under the surface oxide layer, they do not cause any obvious changes to the exterior surface morphology. Consequently, these cavities may escape routine optical or SEM inspection and can therefore impose a significant threat to the reliability of the material, such as oxide scale spalling off from turbine blades or accelerated corrosion. Vacancy supersaturation, activation of a long-range diffusion pathway along the detached interface and the dissociation of hydrogen-vacancy complexes are critical factors affecting this behaviour. These results enrich the understanding of hydrogen-induced interfacial failure at elevated temperatures.